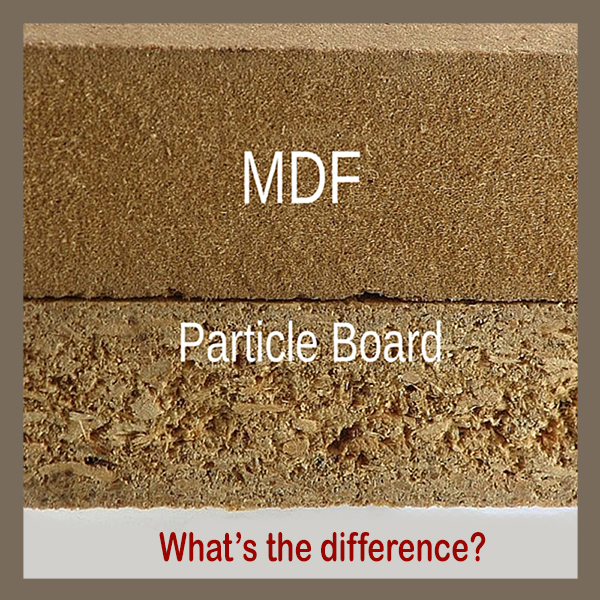

MDF vs. Particle Board – What’s the difference?

Both Medium Density Fibreboard (MDF) and particle board have their uses and best applications. Both are engineered wood composite. Find out what sets them apart and in what building and wood projects each is best utilised.

Medium Density Fibreboard

(MDF) is more dense than plywood and particle board. MDF has an even thickness all throughout and is smooth on both sides. It is a type of hardboard made from wood fibre that has been glued and heated under pressure.

Applications for MDF

- Decorative Wall Cladding

- Wooden Handicraft Items

- Interior Cladding and Panelling

- Furniture building applications

- Shelving

- Cupboards

- Divider Boards

- Panel and Shutter Doors

| Benefits of MDF | Shortcomings of MDF |

|

|

Particle Board

Particle Boards is produced by heat pressing wood chips and saw-dust and immovably squeezing them together to make sheets.

Applications for Particle Board

- Furniture

- Cabinets

- Flooring (beneath carpet or tile)

- Insulation

- Sound Deadening

| Benefits of Particle Board | Shortcomings of Particle Board |

|

|

Ask Us About MDF and Plywoods

| Email Us | Call Us |

Share This!